The PUMP experiment

Predictive Upcycling Maintenance Platform

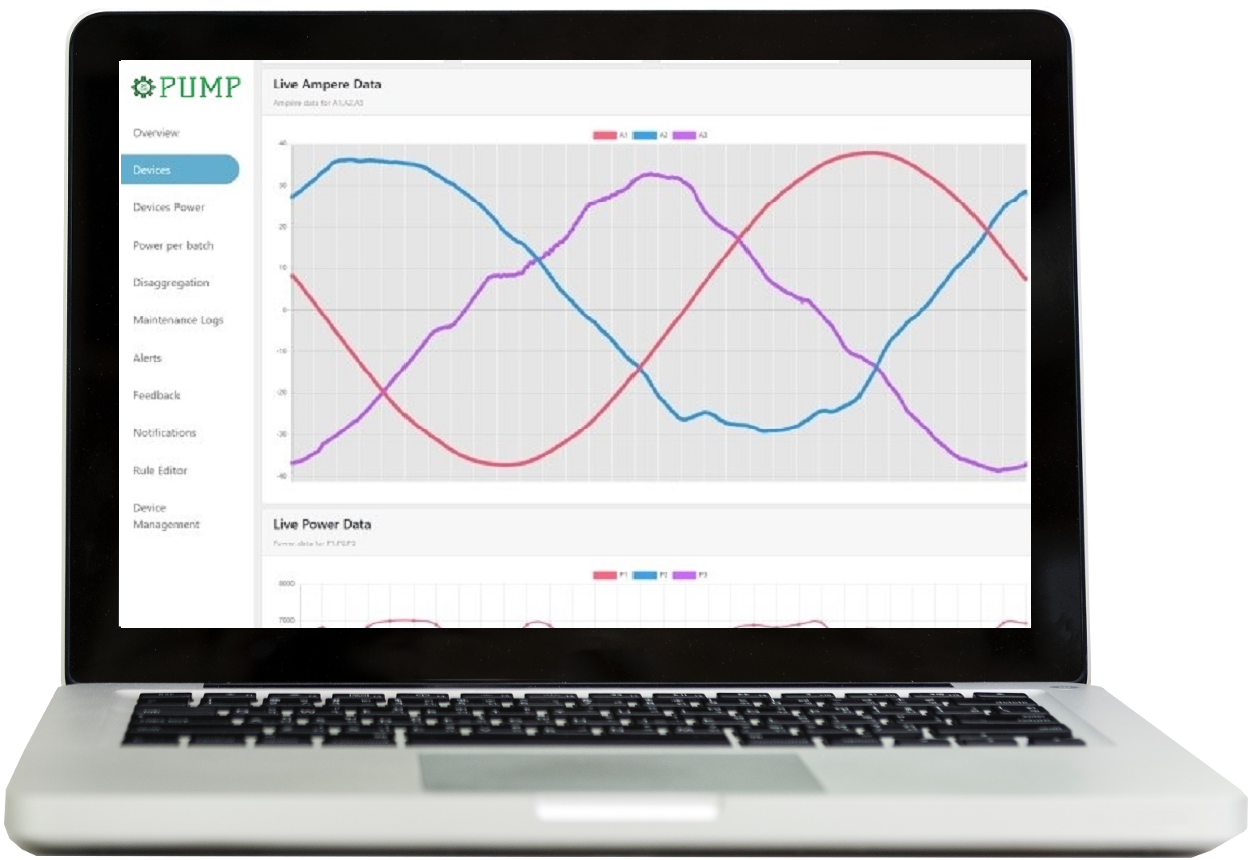

The PUMP project will apply existing non-intrusive energy monitoring tools and advanced ML models to analyse the patterns in electrical loads of machinery equipment, disaggregate component loads, and detect deviations from normal operation in a food processing plant. The project will use the services and technologies of KYKLOS 4.0 project for production optimization; PUMP focuses on Predictive maintenance and will harness the holistic approach of KYKLOS 4.0 to offer enhanced features through the collaborative platform. Data collected from the factory shop-floor regarding the production process and energy consumption of various equipment will be used alongside the technologies of the industrial partners and services of KYKLOS 4.0 platform. Services such as the Maintenance Scheduler will be combined with energy disaggregation and energy analytics to support energy efficiency and efficient machinery health monitoring (MhM). LCA simulations engine will support process efficiency and reduction of waste by producing useful LCA indicators and the Decision Support System will fuse data and enable circular economy features to the developed system. PUMP will utilize various KYKLOS 4.0 services and features and enhance already developed tools to tackle the problem of energy and process efficiency and circularity by combining the outputs of these tools with the DSS system of KYKLOS 4.0.